The Fluke 719 100G is a portable, high-performance electric pressure calibrator designed for calibrating pressure devices with precision and ease, featuring a built-in electric pump for efficient pressure generation.

1.1 Overview of the Device

The Fluke 719 100G Pressure Calibrator is a lightweight, portable device designed for precise pressure calibration. It features a built-in electric pump, enabling quick and accurate pressure generation. Ideal for calibrating pressure transmitters and switches, it includes test leads, alligator clips, and a hose kit. The device supports multiple languages and comes with a user manual on CD-ROM, ensuring ease of use in various environments.

1.2 Key Features and Benefits

The Fluke 719 100G Pressure Calibrator is a high-performance tool featuring a built-in electric pump for efficient pressure generation. Its programmable pump limits prevent over-pressurization, ensuring safety and accuracy. Compatible with various pressure modules, it offers versatility for different applications. Lightweight and portable, it includes test leads, alligator clips, and a multilingual user manual on CD-ROM, making it ideal for field calibration tasks.

Technical Specifications of the Fluke 719 100G

The Fluke 719 100G operates with a pressure range of -12 to 120 PSI and resolution of 0.01 PSI, ensuring high accuracy in pressure calibration tasks.

2.1 Pressure Range and Resolution

The Fluke 719 100G offers a pressure range of -12 to 120 PSI and a resolution of 0.01 PSI, providing precise pressure measurements for accurate calibration of various devices.

2.2 Accuracy and Performance

The Fluke 719 100G delivers exceptional accuracy with precise control, ensuring reliable calibration of pressure devices. Its electric pump provides smooth pressure generation, while programmable limit settings prevent over-pressurization. Designed for P/I transmitter calibration, it offers high performance and portability, making it ideal for field and laboratory use.

Getting Started with the Fluke 719 100G

Unpack and inventory all components, including test leads and quick reference guide. Follow the manual for initial setup, ensuring proper connections and configurations for accurate pressure calibration.

3.1 Unpacking and Inventory

Carefully unpack the Fluke 719 100G and verify all components. Included items are a protective holster, test leads, alligator clips, 9V batteries, a hose kit, and a quick reference guide. Ensure the pressure module and calibration report are present. Check for any damage and compare contents with the manual to confirm completeness before proceeding with setup and operation.

3.2 Initial Setup and Configuration

Insert the pressure module into the sensor port, ensuring proper connection. Install the 9V alkaline batteries and power on the device. Refer to the quick reference guide for specific setup instructions. Allow the calibrator to initialize and perform a self-test. Verify all functions are operational before proceeding to calibration tasks. Ensure the pressure module is correctly recognized by the system for accurate measurements.

Operating the Fluke 719 100G

Operate the Fluke 719 100G by using the electric pump to generate pressure, calibrate devices, and utilize programmable pump limit settings to prevent over-pressurization, ensuring precise control and efficiency in pressure calibration tasks with ease and accuracy.

4.1 Using the Electric Pump

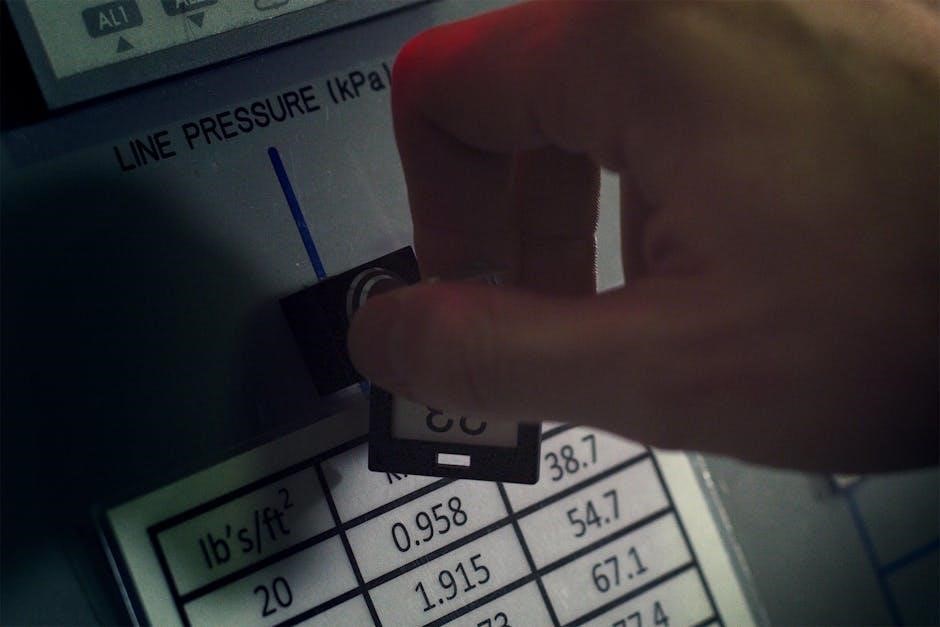

The electric pump on the Fluke 719 100G allows for quick and precise pressure generation. Simply power on the device, set the desired pressure, and the pump will automatically adjust to reach the target. Use the programmable pump limit settings to avoid over-pressurization, ensuring safe and controlled operation. The pump’s design enables easy one-handed operation, saving time during calibration tasks.

- Connect the pressure module to the device.

- Set the desired pressure using the control panel.

- Activate the pump and monitor the pressure reading.

- Adjust as needed to achieve accurate calibration.

This feature enhances efficiency and accuracy in pressure calibration processes.

4.2 Calibration Procedures

Calibration with the Fluke 719 100G involves connecting the device to the pressure transmitter or switch. Set the zero point by ensuring no pressure is applied. Use the electric pump to apply test pressure, then adjust the device under test to match the displayed value. Document the results for accuracy and traceability, ensuring compliance with calibration standards.

- Connect the pressure module to the device.

- Set zero and apply test pressure using the pump.

- Adjust the device under test to match readings.

- Record calibration data for future reference.

This process ensures precise and reliable calibration outcomes.

Pressure Module and Compatibility

The Fluke 719 100G works with interchangeable pressure modules, ensuring compatibility across various pressure ranges. Simply plug the module into the sensor port for accurate measurements.

5.1 Connecting the Pressure Module

To connect the pressure module, plug it into the sensor port on the Fluke 719 100G. The display will initially show dashes and then automatically detect the module, displaying the pressure value. Ensure the module is securely attached to maintain proper communication and accurate measurements during calibration procedures.

5.2 Ensuring Proper Communication

After connecting the pressure module, the device automatically detects and configures it. Ensure all connections are secure to maintain communication. If the display shows dashes or no reading, check the module’s compatibility and connections. Proper communication is essential for accurate pressure measurement and calibration, ensuring reliable performance during field operations.

Maintenance and Troubleshooting

Regularly clean the sensor and check for wear. Address issues like inaccurate readings or pump malfunction by consulting the manual or contacting Fluke support for assistance.

6.1 Routine Maintenance Tips

Regularly inspect and clean the pressure sensor and pump to ensure accuracy. Check hoses for damage or leaks and replace if necessary. Store the calibrator in a protective case when not in use. Follow the user manual’s guidelines for periodic checks and maintenance to prolong the device’s lifespan and ensure reliable performance.

6.2 Common Issues and Solutions

Common issues include pressure module connectivity problems or pump malfunction. Ensure the pressure module is securely connected and communication is established. For pump issues, check for blockages or damage. If the display shows errors, restart the device or refer to the troubleshooting guide in the manual. Addressing these issues promptly ensures optimal performance and accuracy.

Accessories and Optional Equipment

The Fluke 719 100G includes TL75 test leads, a yellow holster, batteries, and a hose kit. Optional equipment such as a carrying case and additional pressure modules enhances functionality and portability for various calibration tasks.

7.1 Included Accessories

The Fluke 719 100G comes with a protective yellow holster, TL75 test leads, a set of alligator clips, two 9V alkaline batteries, and a hose kit. Additional items include a quick reference guide, NIST-traceable calibration report, and a user manual provided on a CD-ROM in 14 languages, ensuring comprehensive support for calibration tasks.

7.2 Recommended Additional Equipment

For enhanced functionality, consider adding extra test leads, alligator clips, or a spare battery pack. A protective carrying case is also recommended to safeguard the calibrator during transport. Additional pressure modules or adapters may be purchased separately to expand compatibility with various pressure devices, ensuring versatility in different calibration scenarios while maintaining precision and reliability.

Safety Precautions and Handling

Always handle the Fluke 719 100G with care, avoiding drops and extreme temperatures. Use proper connectors to prevent damage, and follow guidelines to avoid over-pressurization during calibration.

8.1 General Safety Guidelines

Handle the Fluke 719 100G with care to avoid damage. Ensure proper connections using compatible test leads and connectors. Avoid over-pressurization by adhering to the device’s pressure limits. Always turn off the calibrator before connecting or disconnecting modules. Use protective equipment if necessary, and keep the device away from extreme temperatures or hazardous environments to ensure safe operation and longevity.

8.2 Proper Handling Techniques

Always use the provided test leads and connectors to ensure proper connections. Avoid exposing the device to extreme temperatures or moisture. Regularly clean the calibrator and store it in a protective case when not in use. Never apply excessive force to the hoses or modules, as this may cause damage. Follow all recommended maintenance procedures to ensure optimal performance and longevity of the Fluke 719 100G.

Calibration Certificates and Reports

The Fluke 719 100G provides NIST-traceable calibration reports, ensuring accuracy and compliance. Reports include detailed pressure data and calibration results for precise documentation and record-keeping purposes.

9.1 Understanding Calibration Data

Calibration data from the Fluke 719 100G includes detailed pressure measurements, accuracy specifications, and test results. This data ensures compliance with industry standards and provides a clear record of calibration outcomes for quality assurance and regulatory purposes.

9.2 Generating and Interpreting Reports

The Fluke 719 100G generates detailed calibration reports, including pressure measurements and accuracy data. These reports are NIST-traceable, ensuring compliance with industry standards. Users can easily interpret the data to verify calibration accuracy and maintain precise records for quality control and documentation purposes. The device simplifies report generation, saving time and enhancing workflow efficiency.

Warranty and Support Information

The Fluke 719 100G is backed by a 3-year warranty. For support, contact Fluke’s customer service or visit their official website for assistance and resources.

10.1 Warranty Details

The Fluke 719 100G is covered by a comprehensive 3-year warranty, ensuring protection against defects in materials and workmanship. This warranty period begins from the date of purchase, providing users with peace of mind and reliable support for their investment in this high-precision pressure calibrator.

10.2 Contacting Fluke Support

For assistance with the Fluke 719 100G, users can contact Fluke Support through various channels, including phone, email, or via the official Fluke website. Support is available to address inquiries, troubleshooting, and repair requests. Fluke’s dedicated team ensures prompt and reliable assistance, helping users maintain optimal performance of their pressure calibrator and resolve any technical issues efficiently.

Compliance and Regulatory Information

Approved by global certifications, the Fluke 719 100G meets rigorous safety and environmental standards, ensuring compliance in multiple regions and industries worldwide.

11.1 Regulatory Compliance

The Fluke 719 100G adheres to global regulatory standards, including CE marking and NIST traceability, ensuring compliance with international safety and performance requirements. Designed to meet rigorous industry certifications, it supports calibration needs across various sectors while maintaining adherence to environmental and safety regulations, making it a reliable choice for professionals worldwide.

11.2 Environmental Considerations

The Fluke 719 100G is designed with eco-friendly practices in mind, incorporating recyclable materials and energy-efficient technology. Its lightweight design minimizes carbon footprint during transportation, and the device is free from hazardous substances, aligning with global environmental standards. Proper disposal and recycling of components are encouraged, ensuring minimal environmental impact throughout its lifecycle.

Calibration Best Practices

Ensure accurate results by following pre-calibration checks, using programmable pump settings to avoid over-pressurization, and maintaining proper device setup for optimal performance in various environments.

12.1 Pre-Calibration Checks

Before calibration, ensure the pressure module is securely connected, the electric pump is set to the correct range, and the device is zeroed. Verify battery levels, check for leaks, and confirm all accessories are properly attached. Review the quick reference guide for specific setup requirements to ensure accurate and reliable calibration results every time.

12.2 Post-Calibration Procedures

After calibration, ensure the device is powered off and the pressure module is securely stored. Review the calibration report for accuracy, and archive it for future reference. Clean the equipment, check for any leaks, and perform routine maintenance to maintain precision. Store all accessories in the provided case to protect them from damage.

The Fluke 719 100G offers exceptional efficiency, portability, and reliability, making it an invaluable tool for professionals seeking precise pressure calibration. Its innovative design ensures accuracy and ease of use, while the programmable pump settings enhance safety and convenience, making it a top choice for industrial applications.

13.1 Summary of Key Features

The Fluke 719 100G Pressure Calibrator is a portable, lightweight device designed for accurate pressure calibration. It features a built-in electric pump, programmable pump limits, and compatibility with pressure modules. The calibrator supports multiple pressure ranges, including 100 psi and 7 bar, and offers high resolution and accuracy. It includes test leads, alligator clips, and a multilingual user manual, ensuring versatility and ease of use in various industrial applications.

13.2 Maximizing the Use of the Fluke 719 100G

To maximize the Fluke 719 100G, utilize its programmable pump settings to prevent over-pressurization and ensure precise calibration. Leverage its portability for fieldwork and compatibility with various pressure modules for versatile applications. Regularly update firmware and calibrate modules to maintain accuracy. Use included accessories like test leads and alligator clips for efficient testing, and refer to the multilingual manual for troubleshooting and optimization tips.